Research Article

Effect of storage period on the quality characteristics of two varieties of African Mango Seed Flour at ambient temperature

Adedeji TO*

Department of Food Science and Technology, Osun State Polytechnic, P.M.B. 301, Iree, Nigeria

*Address for Correspondence: Dr. Adedeji TO, Dept of Food Science and Technology, Osun State Polytechnic, P.M.B. 301, Iree, Nigeria, Tel: 08066514332; Email: [email protected]

Dates: Submitted: 30 June 2017; Approved: 08 August 2017; Published: 10 August 2017

How to cite this article: Adedeji TO. Effect of storage period on the quality characteristics of two varieties of African Mango Seed Flour at ambient temperature. Arch Food Nutr Sci. 2017; 1: 012-019.

DOI: 10.29328/journal.afns.1001002

Copyright License: © 2017 Adedeji TO. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Keywords: Ogbono; Storage; Functional; Sensory; Properties

ABSTRACT

The effects of storage of Ogbona seed flour (Irivingia gabonensis and Irivingia excelsa), at ambient condition (30±20C, 65-74% RH) for 0-4 months on some physical characteristics were investigated. The samples were subjected to storage in air tight polyethylene bags for up to four months. Samples were removed at intervals of 0, 1, 2, 3 and 4 months for analysis. The chemical: proximate constituents, free-fatty acids and peroxide values; selected functional properties: water/oil absorption capacity, foam capacity and viscosity and sensory attributes of the samples were investigated. The result shows that there was no observable change in the chemical composition, selected functional and sensory properties of the two varieties of Ogbona seed flours when stored up to two months but decreased from third to fourth month during storage at ambient temperature. Therefore, storage at ambient temperature (30±20C, 65-74% RH) could extend the shelf life of the samples for up to two months in air-tight polyethylene bags of 0.7mm thickness without losing its quality characteristics.

INTRODUCTION

Irvingia gabonensis and Irvingia excelsa are highly, economically important trees native to most southern rain forest of Nigeria [1]. Both varieties top the list of non-timber forest products being clamored for domestication [2,3], and it is fast becoming the tree of choice in agroforestry practices [4-8].

Irvingia gabonensis and Irvingia excelsa are sometimes called bush mango or African mango because the trees bear mango-like fruits [9]. The fruits are broadly ellipsoid, about 4-7cm long, green when unripe and yellow when ripe with a fleshy mesocarp. The fruit pulp is juicy although the taste varies between sweet and bitter [10], and has been shown to have great commercial potentials ranging from the preparation of juices, jams and jellies to wine and soap making [2,4].

Ogbona is widely produced and consumed in Nigeria because of its mucilaginous (draw) property which aids consumption of staple food gels such as tuwo, pounded yam and fufu [11]. ‘Ogbono’ (Irvingia gabonensis) popularly known as bush mango or African mango or wild mango is an indigenous forest tree belonging to the group of plant classified as non-timber forest products [12]. Ogbono (bush mango) belong to the lrvingiaceae family of plant in the species ‘gabonensis’ of lrvingia. The two species: Irvingia gabonensis var. gabonesis and Irvingia gabonensis var. excelsa have some differences. The pulp of the Irvingia gabonesis var. excelsa is said to be eaten, although bitter and acrid with the flavour of turpentine and slightly slimy. Its kernel (seed) contains 54-67% of fatty matter [13], hence it can be classified as an oil seed. The kernel serves as condiment used in thickening and flavouring soups. The more the ground kernel ‘draws’ in soup, the more acceptable it is. Thus, Irvingia gabonensis var. excelsa which draws more than the Irvingia gabonensis var. gabonesis and is more acceptable in soup making in Nigeria [12,13]. On the other hand the pulp of the Irvingia gabonensis var. gabonesis is sweet, smooth in the mouth and has brittle pulp but its kernel draws less than that of Irvingia gabonensis var. excelsa [14]. This study therefore investigated changes in some chemical composition, functional and sensory properties of the two varieties of “Ogbona” powder stored at ambient condition.

MATERIALS

Fresh Irvingia gabonensis and Irvingia excelsa and other ingredients were purchased from a local market: Igbona market, Osun state, Nigeria. They were stored in high density polyethylene bags of 0.7mm at ambient condition (30±2’C, 65-74% RH) for a period of 4 months.

METHODS

Preparation of Ogbono Seeds Flours

Five hundred (500) g of each ogbono seeds were cleaned, sorted, oven dried (500C, 24 h) in a local hot air oven to a constant weight. The dried seeds will be milled into fine powder using Merlex Excella dry mill (Marlex Appliances PVT, Daman) and screened through a 0.50 mm British Standard Sieve. Ten bags each of the samples were separately vacuum sealed in air tight, high density polyethylene bags of 0.7mm thickness.

Quality Characteristics

Ten sealed bags each of the ogbono seed flours were properly labeled and stored at ambient condition (30±20C, 65-74% RH) on cleaned trays in an open space covered with net to keep away house hold insects and pests for up to 4 months. Samples were removed at intervals of 0, 1, 2, 3 and 4 months during storage period and were analysed for quality characteristics: proximate composition (peroxide values and free fatty acid), vitamins: A and C; minerals: K, Mg, Na, Fe; functional properties (viscosity, foaming capacity, water and oil absorption capacity) and sensory properties.

Analysis

Determination of Chemical composition: Peroxide value (PV) and free fatty acid (FFA) content were determined using the methods described by Egan et al. [15], proximate constituents; Vit A, C and minerals were determined according to AOAC [16].

Determination of Functional Properties: Ground Ogbono seeds flours for selected functional properties were defatted using solvent extraction in a soxhlet apparatus for 10h using n-hexane. Viscosity was determined as described by Fleming et al, [17]. Foam capacity was determined as described by Coffman and Garcia [18] water and oil absorption capacities were determined according to the method of Beuchart [19].

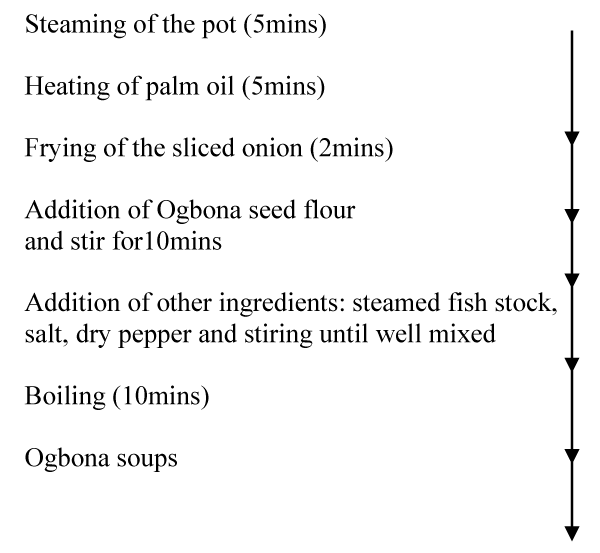

Preparation of Ogbono Soups: The method of Akusu et al. [13], was used in the preparation of the soups. One hundred (100g) each of ground ogbono seed flour that has been air-tight sealed and frozen for 0, 1, 2, 3 and 4 months were removed at intervals and used in the preparation of ogbono soup, respectively based on the recipe in table 1 and according to the procedure outlined in figure 1. After all the ingredients had been added, the pot was allowed to boil for 30 min to make the soups. The soup is allowed to cool, after 30 min, sensory evaluation was conducted on both soups.

| Table 1: Recipee for preparation of Ogbona Soups. | ||

| Ingredients | Irvingia gabonensis | Irvingia excelsa |

| Ogbona Seed flour | 100g | 100g |

| Fish | 50g | 50g |

| Dry pepper | 2g | 2g |

| Palm oil | 50ml | 50ml |

| Onion | 5g | 5g |

| Maagi cubes | 2 | 2 |

| Water | 0.5litres | 0.5litres |

| Salt | A pinch | A pinch |

Sensory Evaluation

A panel of twenty consumers comprising of staff and students of the Department of Food Science and Technology who were used to evaluate the sensory properties of the two varieties of Ogbono (Bush mango) soup prepared from their respective seed flours that were stored at ambient temperature (30±20C, 65-74% RH) for 0, 1, 2, 3 and 4 months. The panelists were selected based on their familiarity with sensory qualities of Ogbono soups and were served in Sensory laboratory at room temperature (30±2°C). A nine-point hedonic scale was used to evaluate appearance, taste, aroma, thickness and overall acceptability of the soups, where 1 and 9 represents dislike extremely and like extremely, respectively according to [20] Iwe method. Water was provided to rinse the mouth between evaluations.

STATISTICAL ANALYSIS

All analysis was done in triplicate determinations±SD and means were separated using Duncan Multiple Range Test.

RESULT AND DISCUSSION

Effect of ambient storage on the chemical composition of Irivingia excelsa and Irivingia gabonensis seeds flour

The chemical composition of Ogbona seed powder of both varieties decreased with storage period tables 2 and 3. There were observable decreases for carbohydrate contents from (33.60±1.04 to 26.65±1.00) % and (28.51±1.45 to 22.98±1.00) %, fat content from (52.13±2.05 to 49.74±2.00) % and (65.35±2.01 to 56.04±1.63) % and protein content from (4.42±0.08 to 3.55±0.02) % and (3.42±0.00 to 2.00±0.01) % with consequence increases in crude fibre from (3.57±0.08 to 5.50±0.05) % and (3.30±1.00 to 5.09±1.05) ash contents from (2.36±0.12 to 3.93±0.06) % and (2.07±0.09 to 3.74±0.02) % for both Irivingia excelsa and Irivingia gabonensis respectively. This may be due to the possible utilization by the associated micro-organisms, slight nutrient depletion, pooled effect of by-products of metabolism and bioconversion into organic acids and other organic compound [21].

| Table 2: Chemical composition of Irivingia excelsa seeds flour during storage at ambient temperature (30±20C, 65-74% RH). | ||||||||||||||

| M | FAT (%) |

MC (%) |

CF (%) |

ASH (%) |

P (%) |

CHO (%) |

FFA (%) |

PV (MEq/kg) |

Vit A (mg/ 100g) |

VIt C (mg/100) |

Fe (mg /kg) |

Mg (mg /kg) |

K (mg /kg) |

Na (mg /kg) |

| 0 |

52.13 ± 2.05 |

3.05 ±0.01 |

3.57 ±0.08 |

2.36 ±0.12 |

4.42 ±0.08 |

33.60 ±1.04 |

2.53 ±0.80 |

60.08 ±2.53 |

0.07 ±0.01 |

2.00 ±0.01 |

45.50 ±1.63 |

0.22 ±0.01 |

0.80 ±0.06 |

0.24 ±0.07 |

| 1 |

52.13 ±2.05 |

3.92 ±0.01 |

3.57 ±0.04 |

2.36 ±0.12 |

4.42 ±0.08 |

33.60 ±1.04 |

2.53 ±0.80 |

60.08 ±2.53 |

0.07 ±0.01 |

2.00 ±0.01 |

45.50 ±1.63 |

0.21 ±0.01 |

0.80 ±0.06 |

0.24 ±0.07 |

| 2 |

52.12 ±2.04 |

3.93 ±0.01 |

3.58 ±0.02 |

2.37 ±0.10 |

4.41 ±0.06 |

33.59 ± 1.03 |

2.50 ±0.70 |

60.07 ±2.50 |

0.06 ±0.00 | 1.99 ±0.01 |

45.49 ±1.60 |

0.20 ±0.01 |

0.79 ±0.05 |

0.23 ±0.06 |

| 3 |

50.11 ±2.00 |

7.78 ±0.00 |

4.44 ±0.03 |

3.15 ±0.08 |

3.97 ±0.04 |

30.55 ±1.01 |

1.50 ±0.50 |

55.41 ±1.80 |

0.02 ±0.00 |

1.55 ±0.00 |

44.59 ±1.20 |

0.15 ±0.00 | 0.70 ±0.01 |

0.18 ±0.05 |

| 4 |

49.74 ±2.00 |

9.63 ±0.00 |

5.50 ±0.05 |

3.93 ±0.06 |

3.55 ±0.02 |

26.65 ±1.00 |

1.02 ±0.35 |

50.77 ±1.70 |

0.01 ±0.00 |

1.47 ±0.00 |

44.43 ±1.15 |

0.10 ±0.00 |

0.60 ±0.01 |

0.15 ±0.03 |

| Table 3: Chemical composition of Irivingia gabonensis seeds flour during storage at ambient temperature (30±20C, 65-74% RH). | ||||||||||||||

| M | FAT (%) |

MC (%) |

ASH %) |

CF (%) |

P (%) |

CHO (%) |

FFA (%) |

PV (MEq/kg) |

Vit A (mg/100g) |

VIt C (mg/100g) |

Fe (mg /kg) |

Mg (mg /kg) |

K (mg /kg) |

Na (mg /kg) |

| 0 |

65.35 ±2.01 |

6.01±0.01 |

2.07 ±0.09 |

3.30 ±1.00 |

3.42 ±0.00 |

28.51 ±1.45 |

2.03 ±0.00 |

50.01 ±2.74 |

0.05 ±0.00 |

1.00 ±0.00 |

35.50 ±2.45 |

0.12 ±0.03 |

0.70 ±0.01 |

0.14 ±0.01 |

| 1 |

56.73 ± 2.00 |

6.00 ±0.04 |

2.07 ±0.07 |

3.30 ±1.00 |

3.40 ±0.03 |

28.50 ±1.32 |

2.03 ±0.01 |

50.01 ±2.61 |

0.05 ±0.00 |

1.00 ±0.00 |

35.50 ±2.36 |

0.12 ±0.02 |

0.70 ±0.01 |

0.14 ±0.01 |

| 2 |

56.72 ±1.90 |

6.01 ±0.02 |

2.08 ±0.04 |

3.31 ±1.01 |

3.39 ±0.02 |

28.49 ±1.28 |

2.02 ±0.08 |

50.00 ±2.50 |

0.04 ±0.00 |

0.98 ±0.01 |

35.49 ±2.21 |

0.11 ±0.01 |

0.69 ±0.00 |

0.13 ±0.01 |

| 3 |

56.61 ±1.72 |

8.64 ±0.03 |

3.10 ±0.06 |

4.65 ±1.06 |

2.07 ±0.04 |

24.93 ±1.04 |

1.30 ±0.03 |

45.41 ±2.32 |

0.02 ±0.00 |

0.55 ±0.00 |

34.08 ±2.12 |

0.05 ±0.00 | 0.53 ±0.00 |

0.12 ±0.00 |

| 4 |

56.04 ±1.63 |

10.15 ±0.00 |

3.74 ±0.02 |

5.09 ±1.05 |

2.00 ±0.01 |

22.98 ±1.00 |

1.00 ±0.05 |

40.77 ±2.11 |

0.00 ±0.00 |

0.49 ±0.01 |

34.03 ±2.01 |

0.03 ±0.00 |

0.40 ±0.00 |

0.10 ±0.00 |

| Keywords: Analysis was done in triplicate determinations ± SD, MC rep moisture content, CF rep crude fibre, P rep Phosphorus, CHO rep carbohydrate, FFA rep free fatty acid, PV rep peroxide value, M rep months. | ||||||||||||||

For the minerals, there were observable decreases from third to fourth month of storage especially for iron (44.59±1.20 to 44.43±1.15) mg/100g and (34.08±2.12 to 34.03±2.01) and magnesium (0.15±0.00 to 0.10±0.00)mg/10g and (0.05±0.00 to 0.03±0.00)mg/100g in tables 2 and 3. Remarkable decreases in vitamin A and C contents were observed during storage period especially after the 2nd month of storage for both Irivingia excelsa and Irivingia gabonensis respectively. Values for Vitamin A and C were (0.07±0.01 to 0.01±0.00) mg/100g and (0.05±0.00 to 0.00±0.00) mg/100 g; (2.00±0.01 to 1.47±0.00)mg/100g and (1.00±0.02 to 0.01±0.00)mg/100g respectively at zero to fourth month storage for both Irivingia excelsa and Irivingia gabonensis respectively. The general decrease in some of the chemical composition of Ogbona seeds flour with increase in storage period may not be unconnected with depletion of nutrient reserve caused by dehydration, respiration and probably gradual disintegration of Ogbona seed flour with storage period [22-25].

The effect of storage at ambient temperature on moisture, free fatty acid content and peroxide values of both Irivingia excelsa and Irivingia gabonensis stored for four months is presented in tables 2 and 3. There was no observable decrease in both Irivingia excelsa and Irivingia gabonensis seed flour stored at ambient temperature for up to two months but there were remarkable decreases after third and fourth months of storage at ambient temperature for free fatty acid content (1.05±0.50 to 1.02±0.35) % and (1.30±0.00 to 1.00±0.00) % and peroxide value (55.41±1.80 to 50.77±1.70) MEq/kg and (45.41±2.32 to 40.77±2.11) MEq/kg. This might be due to the effects of lipid oxidation which causes off-odours and off–flavours, hence the storage life of fatty foods is more limited than non-fatty foods [26]. The observable decrease in Irivingia excelsa and Irivingia gabonensis respectively seed flours after third and fourth months of storage at ambient temperature could also be attributed to the slow diffusion of oxygen through the gas-impermeable polyethylene bag of 0.7mm thickness used in packaging the Ogbono seed flours. Egan et al., 1981 reported that acidity and a [15] rancid taste often begins to be noticeable in foods when free fatty acid content is about 0.5 to 1.5% oleic acid and peroxides values are between 20 to 40 MEq/kg. The result obtained in this study reveals that after four months of storage at ambient temperature (30±20C, 65-74% RH), the free fatty acid contents of both varieties of Ogbono seed flours were slightly above the safe limit while the peroxide values were still within the safe limit.

Effect of ambient (30±20C, 65-74% RH) storage on the functional properties of Irivingia excelsa and Irivingia gabonensis seeds flour

Effect of storage on some functional properties of water/oil absorption, foam capacity and viscosity of vacuum sealed packaged ground Ogbono seed flours stored for four months at ambient temperature (30±20C, 65-74% RH) is as shown in tables 4 and 5. There was no observable change in the selected functional properties of both Irivingia excelsa and Irivingia gabonensis seed flours stored for up to two months, however all the selected functional properties of both flour samples decreased during the third and four months of storage at ambient temperature. This observation is in agreement with the work of Fellow [27], that there is a slow loss of quality owing to both chemical changes in some foods and enzymic activities during food storage. The viscosity on the other hand decreased from (9.28±0.09 to 7.01±0.07 ) pa/s and (8.98±0.06 to 6.03±0.07 ) pa/s; foam capacity from (2.15±0.32 to 1.20±0.28) ml and (2.00±0.32 to 0.78±0.20 ) ml from 0 and 4months for both Irivingia excelsa and Irivingia gabonensis seed flour respectively.This became pronounced after two months of storage probably be due to increase in crude fibre and ash with possible decrease in pectic and mucilaginous (glycoprotein) substances which may have been caused by respiration with subsequent decrease in carbohydrate and energy [23,28]. Hence, Ogbona seed flour should be consumed after 2 months of storage in order to preserve its nutrients and retain its functional properties.

| Table 4: Functional Properties of Irivingia excelsa Seed Flours stored at ambient temperature (30 ± 20C, 65-74% RH). | ||||

| Months | Viscosity (pa/s) |

Foam Capacity (ml) |

Oil Absorption Capacity (g/g) |

Water Absorption Capacity (g/g) |

| 0 | 11.45±1.09 | 3.53 ±0.56 |

85.40 ±2.75 |

118.70 ±3.48 |

| 1 | 11.45 ±1.09 |

3.53 ±0.56 |

85.60 ±2.77 |

118.70 ±3.48 |

| 2 | 11.44 ±1.07 |

3.54 ±0.49 |

85.60 ±2.80 |

118.69 ±3.45 |

| 3 | 9.28 ±0.09 |

2.15 ±0.32 |

82.08 ±2.11 |

116.00 ±3.65 |

| 4 | 7.01 ±0.07 |

1.20 ±0.28 |

79.13 ±2.00 |

114.19 ±3.10 |

| Keywords: Analysis was done in triplicate determinations ± SD. | ||||

Effect of ambient (30±20C, 65-74% RH) Storage on the Sensory Properties of Irivingia excelsa and Irivingia gabonensis Seed Flours

The effects of storage at ambient temperature on the sensory properties of soups prepared from Ogbono seed flours are shown in tables 6 and 7. There was no observable change in the sensory properties of soups prepared from both Irivingia excelsa and Irivingia gabonensis seed flour stored at ambient temperature up to two months. However, after third and fourth months, there was a remarkable change in sensory attributes of taste, aroma, thickness, drawability and overall acceptability of “Ogbono” seed flour. Cardello reported that to the consumer, the most important quality attributes of food are its sensory characteristics [29]. He further concluded that sensory attributes substantially influence the acceptability of foods. He also stated that the aim of a food processor is to find improvement in processing technology which retains or create desirable sensory qualities.

| Table 6: Sensory Properties of Ogbona soups prepared from Irivingia excelsa Seed Flours stored at ambient temperature (30 ± 20C, 65-74% RH). | ||||||

| Months | Taste | Thickness | Appearance | Flavour | Drawability | Overall accept |

| 0 | 7.55 | 7.71 | 8.04 | 8.24 | 7.93 | 8.85 |

| 1 | 7.54 | 7.70 | 8.03 | 8.22 | 7.92 | 8.83 |

| 2 | 7.53 | 7.69 | 8.02 | 8.20 | 7.90 | 8.80 |

| 3 | 6.05 | 6.04 | 7.53 | 7.17 | 8.15 | 7.01 |

| 4 | 5.42 | 5.12 | 6.01 | 6.50 | 7.04 | 6.26 |

| Keywords: Analysis was done in triplicate determinations. | ||||||

| Table 7: Sensory Properties of Ogbona soups prepared from Irivingia gabonensis Seed Flours stored at ambient temperature (30 ± 20C, 65-74% RH). | ||||||

| Months | Taste | Thickness | Appearance | Flavour | Drawability | Overall accept |

| 0 | 6.55 | 6.71 | 7.04 | 7.24 | 6.93 | 7.85 |

| 1 | 7.54 | 7.70 | 8.03 | 8.22 | 7.92 | 8.83 |

| 2 | 7.53 | 7.69 | 8.02 | 8.20 | 7.90 | 8.80 |

| 3 | 6.05 | 6.04 | 7.53 | 7.17 | 8.15 | 7.01 |

| 4 | 5.42 | 5.12 | 6.01 | 6.50 | 7.04 | 6.26 |

| Keywords: Analysis was done in triplicate determinations. | ||||||

CONCLUSION AND RECOMMENDATION

The results obtained from this study revealed that all the chemical composition, selected functional and sensory properties of both varieties of Irivingia excelsa and Irivingia gabonensis seed flours decreased after two months of storage at ambient temperature. This therefore suggests a need for additional method of preservation in order to extend the shelf life of the seed flour like inclusion of spices, frozen storage and the use of preservatives or irradiation. It is recommended that Ogbona seed flour stored at ambient temperature should be consumed within 2 months of storage in order to preserve the nutrients and retain its functional properties. However, Irivingia excelsa is much more preffered to Irivingia gabonensis because of its higher chemical composition and functional properties. This also agrees with the result of the sensory evaluation on Ogbona seed flour.

REFERENCES

- Harris DJ. A revision of the Irvingiacea in Africa. Bulletin du Jardin Botanique National de Belgique. 1996; 65: 143-196. Ref.: https://goo.gl/noKWpy

- Ndoye O, Pérez MR, Eyebe A. The markets of non-timber forest products in the humid zone of Cameroon. Ref.: https://goo.gl/tc9C5R

- Leakey R, Schrecheriberg K, Tchoundjev Z. The participatory domestication of West African indigenous fruits. Int For Rev. 2003; 5: 338-347. Ref.: https://goo.gl/XshcMS

- Okafor JC. Selection and improvement of indigenous tropical fruit tree: Problems and prospects. J Forest Res. 1985; 1: 87-95. Ref.: https://goo.gl/oL9C4K

- Okafor JC. Improving edible species of forest products. Unasylva. 1991; 165: 17-23. Ref.: https://goo.gl/wQSe7M

- Okafor JC, Ejkiofor M, Okolo HC. Development and utilisation of disappearing and under 7536. Biodiversity Support Programme. WWF, Washington, D.C.

- Leakey RRB. Farmers top priority fruit trees. Agris. 1999; 11: 11-15. Ref.: https://goo.gl/oRCAQe

- Koyejo AO, Omokhua G. Propagation studies on Irvingia wombulu (syn.Excelsa) Ex. Okafor and agroforestry specis. In: Proceedings of FAN Conference held in Abuja. 2001; 183-187.

- Matos L, Nzikou JM, Matouba E, Pandzou-Yembe VN, Mapepoulou TG, et al. Studies of Irvingia gabonensis seeds kernels: Oil technological applications. Pak J Nutr. 2009; 8: 151-157. Ref.: https://goo.gl/5EFFa4

- Lowe AJ, Gillies ACM, Wilson J, Dawson IK. Conservation genetics of bush mango from central/west Africa: Implications from random amplified polymorphic DNA analysis. Mol Ecol. 2000; 9: 831-841. Ref.: https://goo.gl/DGgg39

- Fayemi PO. Nigerian Vegetables. Heinemann Educational Books (Nigeria) Plc. 1999; 12-36. Ref.: https://goo.gl/kD3Fsn

- Atangana AR, Techoundjeu Z, Foldout JM, Asaah E, Dumb M, et al. Domestication of Irvingia gabonensis: 1. phenotypic variation in fruit and kernels in two population from Cameroon. Agrioforestory System. 2001; 53: 55-64. Ref.: https://goo.gl/QEEtFn

- Akusu MO, Kiin-Kabari DB. Effect of storage period on selected functional, chemical stability and sensory properties of bush mango (Irvingia gabonensis) seed flour. African Journal of Food Science and Technology. 2013; 4: 136-140. Ref.: https://goo.gl/QmfaK7

- Hyman EL. Technology and the organization of production processing and marketing of non-timber forest products. 1995; 197-199. Ref.: https://goo.gl/xgUUgK

- Egan H, Kirk RS, Sawyer, R. Pearson’s chemical analysis of foods (8thed.). 1981; 591. Ref.: https://goo.gl/HTDsnq

- AOAC. Official Methods of Analysis of AOAC International, 20th Edition. 2016. Ref.: https://goo.gl/ayrNc4

- Fleming SE, Soculski FW, Hamon NW. Gelation and thickening phenomena of vegetable protein Products. J Food Sci. 1975; 40: 805-807. Ref.: https://goo.gl/pRvrQc

- Coffmann CW, Garciaj VV. Functional properties and amino acid content of a protein isolate from mung bean flour. J Food Tech. 1977; 12: 473-484. Ref.: https://goo.gl/x6t59r

- Beuchart LR. Functional and electrophoretic characteristics of succinylated peanut flour protein. J Agric Food Che. 1977; 25: 258-261. Ref.: https://goo.gl/b3kcet

- Iwe MO. Handbook of sensory methods and analysis. Re-joint Communications Services Ltd. 2010; 75-78. Ref.: https://goo.gl/nZGDG5

- Schippers RR. African Indogenous Vegetables.An Overview of the Cultivated Species. Department for International Development. 2010; 103-118. Ref.: https://goo.gl/f9LzgK

- lhekoronye Al, Ngoddy PO. Integrated Food Science and Technology for the Tropics. 1985; 386. Ref.: https://goo.gl/u4vdXW

- Braverman JBS. Introduction to the Biochemistry of Foods. 1991. Ref.: https://goo.gl/XdYtv3

- Idowu MA, Akindele SA. Effect of storage of cassava roots on the chemical composition and sensory qualities of gari and fifu. Food Chem. 1994; 51: 421-424. Ref.: https://goo.gl/uHCbah

- Osagie AU, Onigbinde AO. Effects of growth, maturation and storage onthe composition of plant foods. In: Nutritional Quality of Plant Foods.Post-harvest Research Unit. 1999-220.

- Erickson MA. Lipid oxidation: flavour and nutritional quality deterioration in frozen foods. Quality in frozen food. 1997; 141-173. Ref.: https://goo.gl/Qy6uDg

- Fellows PJ. Food Processing Technology: Principles and practice. Woodhead publishing. Ref.: https://goo.gl/1DUJX8

- Uzo TO, Ojiakor UU. A physical method for measuring fruit quality. J Food Sri. 1998; 45: 310-315.

- Cardello AV. Perception of food quality ln: I.A Taub and R.P Singh (eds). Food storage stability. CRC Press. 1998; 1-38. Ref.: https://goo.gl/avE6F3

- Ngondi JL, Oben JE, Minka SR. The effect of Irvingia gabonensis seeds on body weight and blood lipids of obese subjects in Cameroon. Lipids in health and Disease. 2005; 4: 12-15. Ref.: https://goo.gl/d1rUz9

- Leakey RRB, Fondoun JM, Atangana A, Tchoundjeu Z. Quantitative descriptors of variation in the fruits and seeds of Irvingia gabonensis. Agrofor, 2000; 50: 47-58. Ref.: https://goo.gl/kk6v1Z